Description

Features

1 to 8 color automatic UV bottle screen printing machine

Fast print speeds up to 4200 bottles per hour

Accurate color to color registration

Prints on round, oval and square bottles

Mechanical driven bottle transport in high stability

Omron PLC and touch screen controlled

Italy SITI brand main motor

Intelligent UV system saves energy consumption

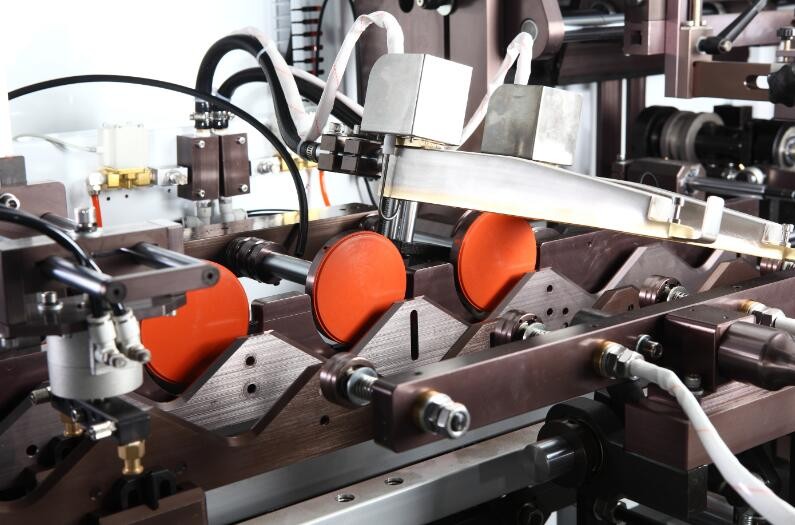

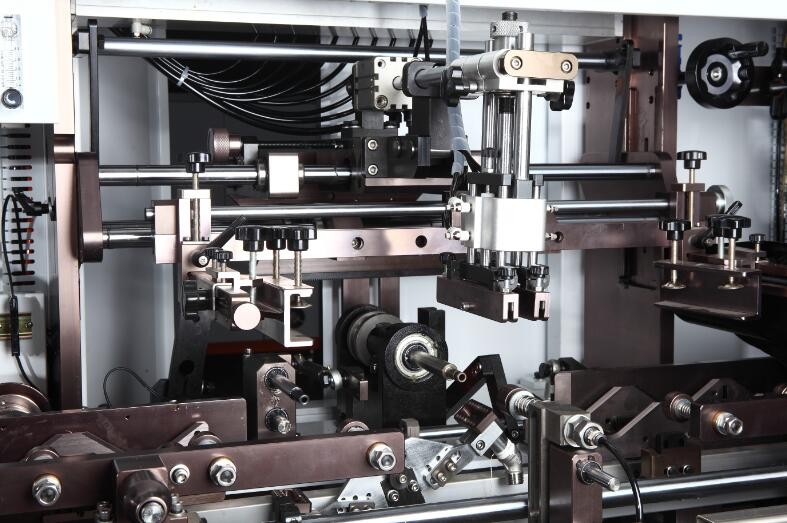

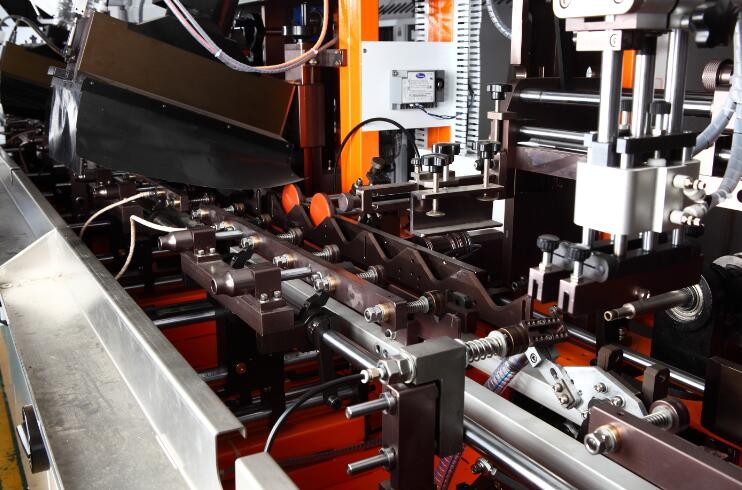

Integrated anti-static dust blowing and bottle surface flame treating

The HY-1000 series of precision automatic UV screen printing machines designed for printing onto large pails, 25 litre buckets and 2 litre sized plastic bottles. The HY-1000 automatic UV screen printing press can also screen print on beer pony kegs, stainless-steel thermos bottles, jars & containers. The HY-1000 feature

a DC motor controlled linear walking beam system that is solidly built to provide accurate color to color print registration with print speeds up to 22 pieces per minute. Once bucket enter the HY-1000 machinery they are automatically flame treated and fed through each of the subsequent printing and UV curing stations.

Main Specifications

Model NO.:

HY-1000-1

Bucket size:

Diameter: φ150-350mm, Height: 200-400mm

Max. print area:

L900 x W250mm

Max. printing capacity:

22 pcs/min

Registration tolerance:

+/- 0.2 mm

Infeed conveyor:

1 unit, length: 2 meters

Flame treating system:

3 units, LP gas

Motor:

ITALY SITI

Print head:

1 unit

UV system:

1 unit intelligent UV system, 5KW per each

Outfeed conveyor:

1 unit, Length: 2 meters

Control system:

OMRON PLC & Touch Screen

Frequency Converter:

OMRON

Drive:

Mechanical Driven

Pneumatic parts:

FESTO or SMC

Electrical:

380V 3phase 50Hz

Air requirement:

5-7 bar

Air consumption:

100 liter/ minute max. (per color)

Power consumption:

20 KW/color x 1

Machine size(LxWxH):

Main machine: 7000x2900x2000mm

Weight:

2500 KG