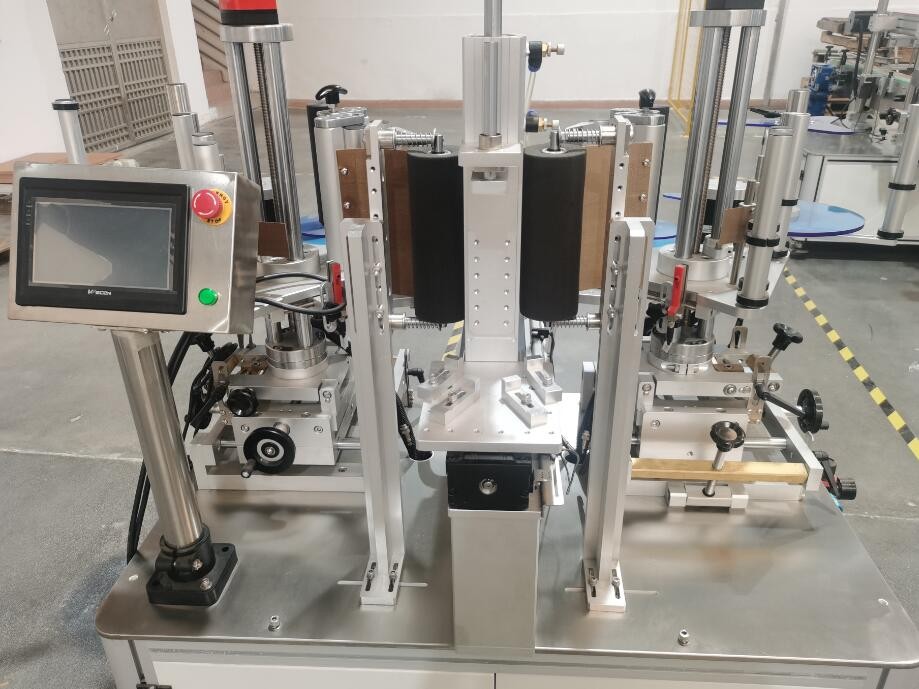

Description

1.For all kinds of double side labeling ,such as flat bottle, cosmetics boxes, plastic cap labeling, etc.

2.Date printer can be added to printer production date ,batch lot and expiry date while labeling.

3.Widely used in food, cosmetic, chemical, pharmaceutical and other industries.

4.support customization.

Features

1) Control system: Japanese Panasonic control system, with high stability and extremely low failure rate.

2) Operation System: Color touch screen, directly visual interface easy operation, Chinese and English available, Easily to adjust all electrical paramete

counting function, which is helpful; for production management.

3) Detection System: Using German SICK label sensor and Japanese Panasonic sensor, which are sensitive to label and product, thus ensure high acc

labeling performance , Greatly saves labor.

4) Alarm Function: The machine will give an alarm when problem occur, such as label spill, label broken, or other malfunctions.

5) Machine Material : The machine and spare parts all use material stainless steel and anodized senior aluminum alloy, with high corrosion resistance a

6) Equipment with a voltage transformer to adapt to local voltage

|

Parameters |

Date |

|

Label specification |

Adhesive, sticker, transparent or opaque |

|

Labeling Tolerance |

±0.5mm |

|

Capacity(pcs/min) |

15~30 |

|

Suit bottle size(mm) |

L:50~350W:20~200H:50~400,canbe customized |

|

Suit label size(mm) |

L:20~100; W(H):15~110 |

|

Machine size(L*W*H) |

≈1220*1250*1470(mm) |

|

Pack size(L*W*H) |

≈1280*1300*1500(mm) |

|

Voltage |

220V/50HZ; can be customized |

|

Power |

780W |

|

N*W(kg) |

≈270 |

|

G*W(kg) |

≈350 |

|

Label roll |

76mm inner corner |

|

Air supply |

0.4~0.6Mpa |